Stud & Track Machine

Suspended Ceiling and Drywall Stud & Track making machine

Suspended Ceiling and Drywall Stud & Trackmaking machineSuspended Ceiling and Drywall Stud & Trackmaking machine could be used to make the Drywall Stud & Trackin batch. RUSUS steel channel is made from hot cold-rolled galvanized steel, and we adopt advanced process and technology to produceit. According to customer's requirement, special specification is accepted for OEM.Take the following Suspended Ceiling and Drywall Stud & Trackdrawing for example and show you the elements of the machine:Steel Profile - Suspended Ceiling and Drywall Stud & Trackmaking machine design like this:Suspended Ceiling and Drywall Stud & Trackmaking machine parameters for your reference:Processing material: GI...

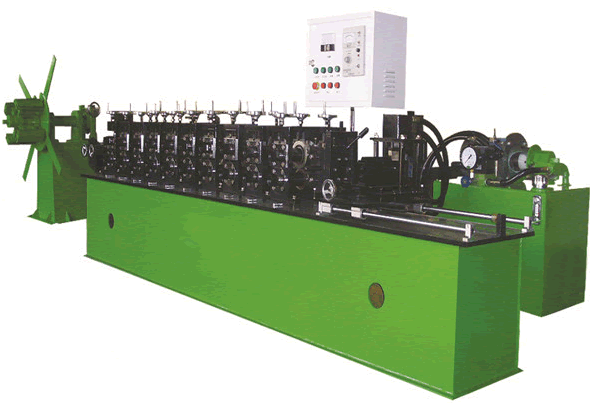

Suspended Ceiling and Drywall Stud & Track making machine

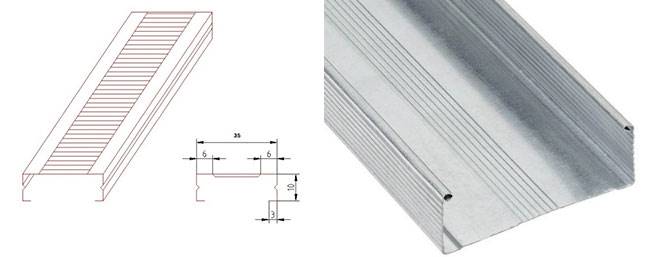

Suspended Ceiling and Drywall Stud & Track making machine could be used to make the Drywall Stud & Track in batch. RUSUS steel channel is made from hot cold-rolled galvanized steel, and we adopt advanced process and technology to produce it. According to customer's requirement, special specification is accepted for OEM. Take the following Suspended Ceiling and Drywall Stud & Track drawing for example and show you the elements of the machine:

Steel Profile - Suspended Ceiling and Drywall Stud & Track making machine design like this:

Suspended Ceiling and Drywall Stud & Track making machine parameters for your reference:

Processing material: GI

Material thickness: 0.4---0.8mm

Material hardness: 550 MPA---350 MPA

Formed width: 35mm

Working speed: 25m/min

| Un-coiler SystemUsage: It is used to support the steel coil and uncoil it in a turntable way.Passive uncoil pulled by roll forming systemLoading capacity: 1.5TUncoiling width: 300mmInner diameter: 450-550mm |

| Entry BeachUsage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

Main Roll Forming System | Feature: Ensure stability, precision and lifetime.Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission( the first and the |

Shearing Mechanism

| Function : Automatic cutting controlled by PLC |

| It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. | |

| Material of blades: Gcr12 quenchedPower supply : hydraulic powerFrame : Pillar style with rack & pinion systemStroke switch : non-contact photoelectric switch | |

| Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

Suspended Ceiling and Drywall Stud & Track making machine feature;

By this machine, you can make it work at the speed of 25 meter per minute.

By the spacer adjustment, one machine can make many different types profiles.

Long time to use and easy to use.

Simple connect the electricity and then you can make it work easily.

Description of galvanized drywall metal studs and tracks

| Material | Carbon steel or SS304 or SS316 |

| Surface Treatment | HDG(hot dipped galvanized ),Pre-galvanized,Electrical-galvanizing(yellow or white),powder coating(Black,Green,White,Grey,Blue)etc. |

| Lengths | Either 10FT or 20FT or cut into the length according to clients' requirements |

| Thickness | 1.5mm, 1.8mm,1.9mm,2.0mm, 2.3mm,2.5mm ,2.7mm, |

| Holes | 28*14mm,18*9mm,13.5*63mm,11*25mm,11*30mm etc |

| Style | Plain or Slotted |

| MOQ | 1000 Pieces |

| Packaging | In Bundles and fasten with steel strips or by wooden pallets |

Here is the installation of the drywall metal studs and tracks:

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line