Stud & Track Machine

Greenhouse Metal Profile Roll Forming Machine

Greenhouse Metal Profile Roll Forming MachineGreenhouse Metal Profile Roll Forming Machine is designed to make the metal profiles for the greenhouse in batch fully automatically. As the greenhouse elements includes steel angle, channel, conduit, or a hat-shaped fastener.Here are some drawing profiles for Greenhouse Metal Profile for your reference:Here are Greenhouse Metal Profile pictures for your reference:Greenhouse Metal Profile Roll Forming Machine Pictures for your reference:Here we take the Grape strut for example rolling forming machineGrape strut for example rolling forming machinegreenhouse, it is consist ofthe following elements:single Arm Uncoiler, leveler, servo feeder and punch...

Greenhouse Metal Profile Roll Forming Machine

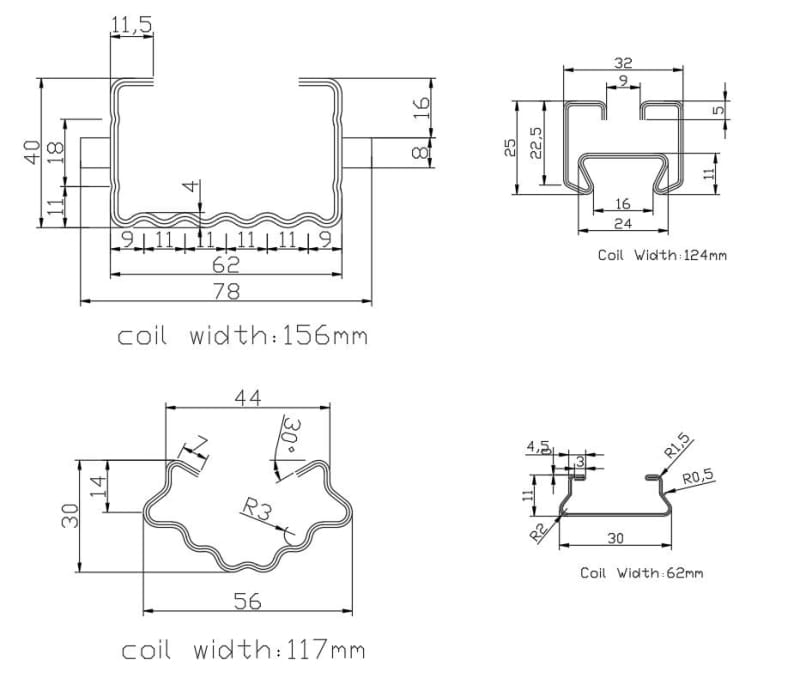

Greenhouse Metal Profile Roll Forming Machine is designed to make the metal profiles for the greenhouse in batch fully automatically. As the greenhouse elements includes steel angle, channel, conduit, or a hat-shaped fastener. Here are some drawing profiles for Greenhouse Metal Profile for your reference:

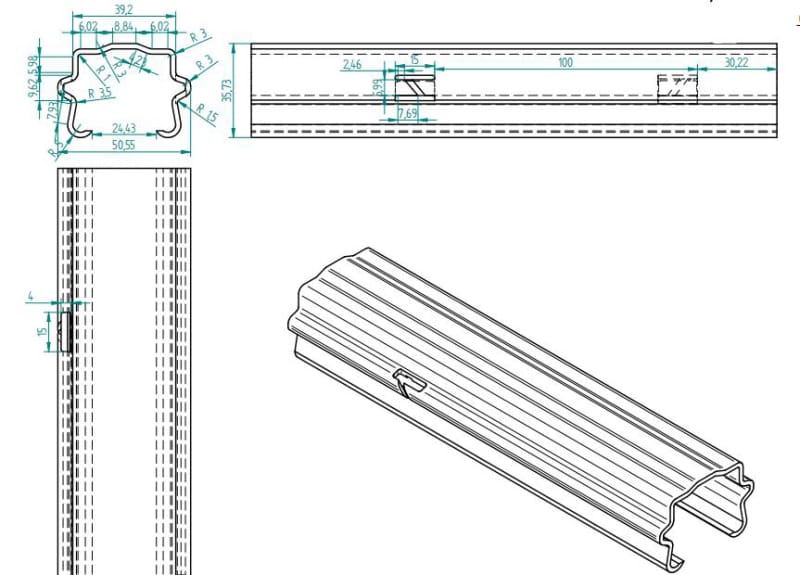

Here are Greenhouse Metal Profile pictures for your reference:

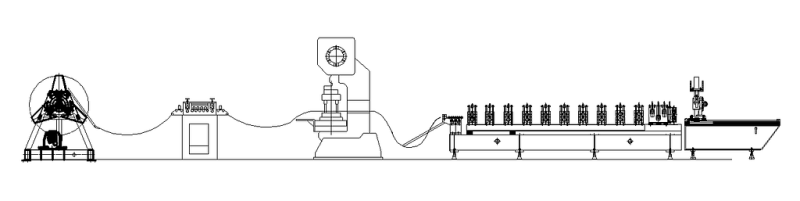

Greenhouse Metal Profile Roll Forming Machine Pictures for your reference:

Here we take the Grape strut for example rolling forming machine

Grape strut for example rolling forming machine greenhouse, it is consist of the following elements: single Arm Uncoiler, leveler, servo feeder and punch machine, feeder and guider Roll forming machine, cutoff device, controlled panel, hydraulic station collection Table, Spare Parts.

Grape strut for example rolling forming machine Profile Roll Forming Machine Layout

Uncoiling– Leveling– Servo Feeding and Punching– Guiding– Roll Forming–Cutting

Here are some Grape strut rolling forming machine parameters for your reference:

1.Feature:Ensure the stability, accuracy and long life

2.Main forming machine Size 8500mm*1200mm*1500m(L*W*H)

3.Main forming machine weight: 8.5Ton

4.Voltage: 380V 50Hz 3 Phrase (380 V is China normal voltage, but the voltage can be customize by customer.)

5.Method for fixing roller: Molding Memorial arch frame

6.Material of shafts 45# steel Thermal refining

7.Transmission method Gear

8.The main shaft material No. 45 steel quenching and tempering treatment

9.Outer shaft diameter 70mm

10.Wheel material Quenching process of GCr15 bearing steel HRC58-60

11.Roller21 stations

12.The main motor power 7.5kw

13. All Electrical control part as ABB

14. Hydraulic pump and motor Germany.

15. Bearings are SK JAPAN.

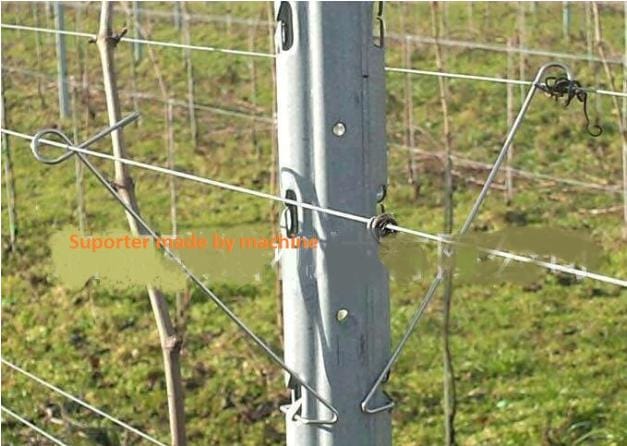

Vineyard Pole rolling machine working video for your reference:

Here are some pictures of how vineyard poles used:

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line