Decoiler

Mirror Metal steel water ripples metal sheet embossing machine

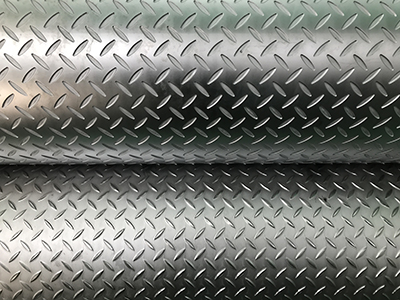

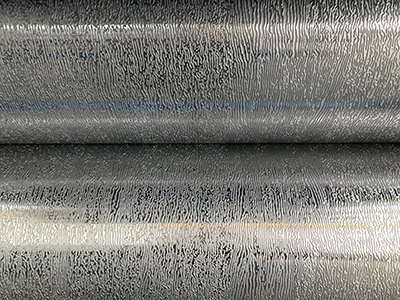

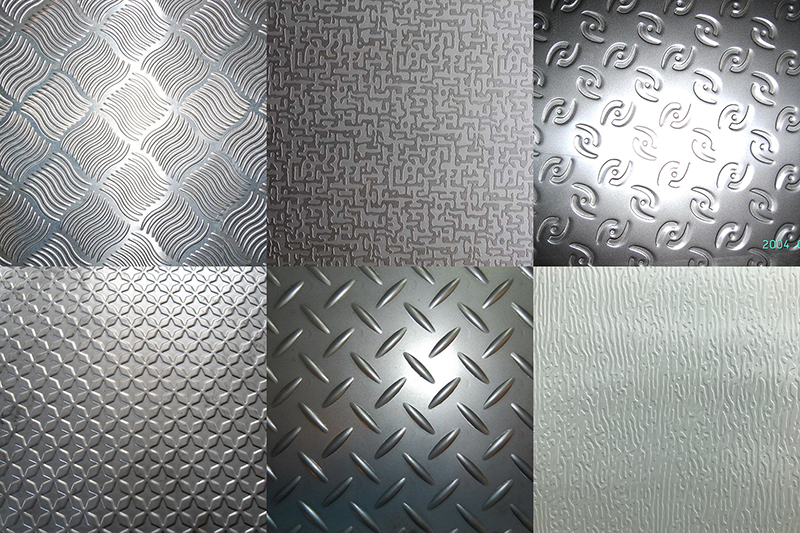

Stainless steel water ripples metal embossing machine Stainless steel water ripples metal embossing machine is designed to make the metal embossing in batch fully automatically. Forthe water ripples metal embossing, we mainly use the stainless steel and as to the water ripples we have three types like big waves, middle waves and small waves. Here are some pictures for your reference:Products DisplayIntroductionMetal sheet embossing is a stamping process to produce various designed patterns in sheet metal by passing the sheet in roll or a strip of metal between rolls of the desired patterns. Metal sheet or steel coil is fed into the male and female roller dies on a sheet metal embosser so tha...

Introduction

Other design

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line