Ceiling Panel Machine

ceiling channel roll forming machine

Zhongtuo ceiling channel roll forming machine is professionally developed for making ceil channels in a fast speed and high quality standard. The entire range is fabricated using high quality raw materials at our modern and well-equipped manufacturing facility. The finished products of this machine could be customized according to customers need. Normally speaking, C, Z, ceiling channel can produce two drawing profiles products without changing rollers. Our machine has a ability to produce bulk needs of ceiling section of customer within the specific time frame.ÂElements of Zhongtuo ceiling channel roll forming machine:D-coilerEntry Gate with levelingRoll Forming Line with 18 stationsPLC st...

Zhongtuo ceiling channel roll forming machine is professionally developed for making ceil channels in a fast speed and high quality standard. The entire range is fabricated using high quality raw materials at our modern and well-equipped manufacturing facility. The finished products of this machine could be customized according to customers need. Normally speaking, C, Z, ceiling channel can produce two drawing profiles products without changing rollers. Our machine has a ability to produce bulk needs of ceiling section of customer within the specific time frame.

Elements of Zhongtuo ceiling channel roll forming machine:

D-coiler

Entry Gate with leveling

Roll Forming Line with 18 stations

PLC station and cutting unit

Basic information of Zhongtuo ceiling channel roll forming machine:

| D-coiler | Coil weight : 5 MT Max Coil width : 1250 MM Coil bore: 450 MM min, 510 MM max dia. Mandrel movement : Manually djusted Back Tension : Manually adjusted |

| Entry Gate | Entry gate will be provided for making sure to delivering sheet to roll former |

| Mill stands (Station) | The stands (GCr12MoV) installed on machine and their alignment can be easily done due to guide ways arranged on the bed of the machine. The mill stands will be arranged to locate shafts mounted on taper bearings. For different sizes or shapes ceiling channel, simply change stands manually or automatically |

| Main frame of machine | It uses 25mm thickness quality steel |

| Roll shafts | The roll shafts dia. 70mm will be manufactured from quality steel and will be keyed to locate tooling. |

| Control system | PCL computer or station |

| Counter | 1 set |

| Runout table | Quality steel |

| Drive | Gear or case of differential for high speed |

| Cutting Unit (Servo) | Flying track cutting saw |

| Hydraulic station |

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

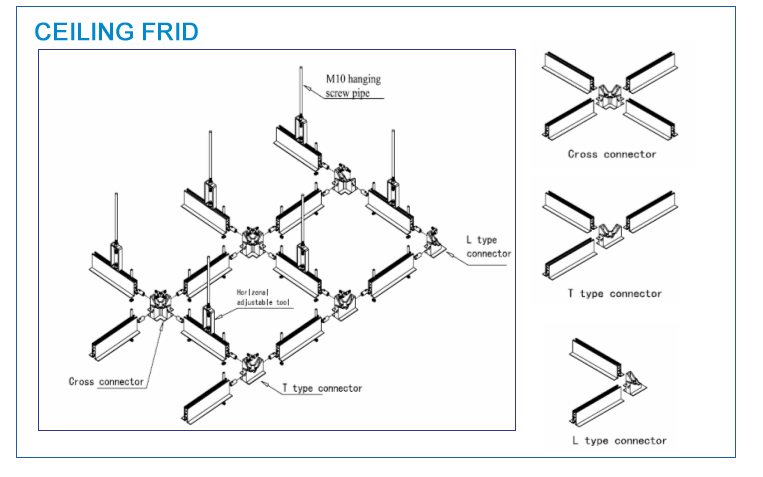

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line