C & Z Purline Machine

Fully automatic Z purlin rolling forming machine

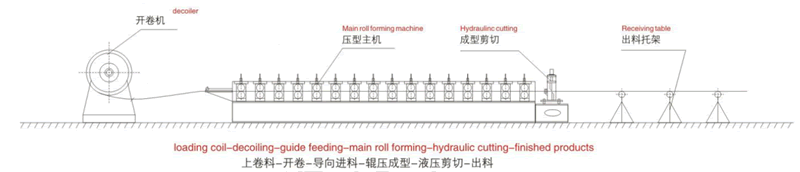

Fully automatic Z purlin rolling forming machineFully automatic Z purline rolling forming machine is professionally designed to make the Z purline in batch. It allows to do online punching, online punching logos. It composed by thefollowing elements: decoiler, guiding platform,main machine of roll forming, cutting device, electric motor,hydraulic station,Delta PLC control system, run out table. Take the following drawing profile for example:Z purlin machine working process:Decoiler→ →Feeding material into machine→Roll forming machine→Measure length→Hydraulic cutting→Finished ProductsZ purlin rolling forming machine:Fully Automatic Changed Z Shape Purlin Roll Forming Machine:MainTechnic...

Fully automatic Z purlin rolling forming machine

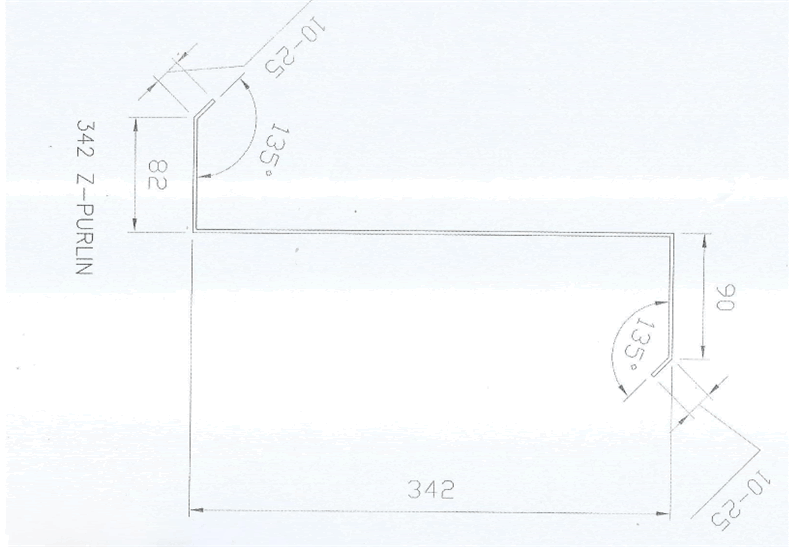

Fully automatic Z purline rolling forming machine is professionally designed to make the Z purline in batch. It allows to do online punching, online punching logos. It composed by the following elements: decoiler, guiding platform,main machine of roll forming, cutting device, electric motor,hydraulic station,Delta PLC control system, run out table. Take the following drawing profile for example:

Z purlin machine working process:

Decoiler→ → Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

Z purlin rolling forming machine:

Fully Automatic Changed Z Shape Purlin Roll Forming Machine:

Main Technic Parameter:

| Size | 7800*1500*1600mm |

| Weight | 9000KGS |

| Voltage | 380V/60HZ/3PH |

| Hydraulic Motor Power | 22KW |

| Motor Power for auto adjustment size | 0.37KW*2+0.75KW |

| Motor Power for auto guide device | 0.18KW*2 |

| Motor Power for auto adjustablehole distance device | 0.18KW*2 |

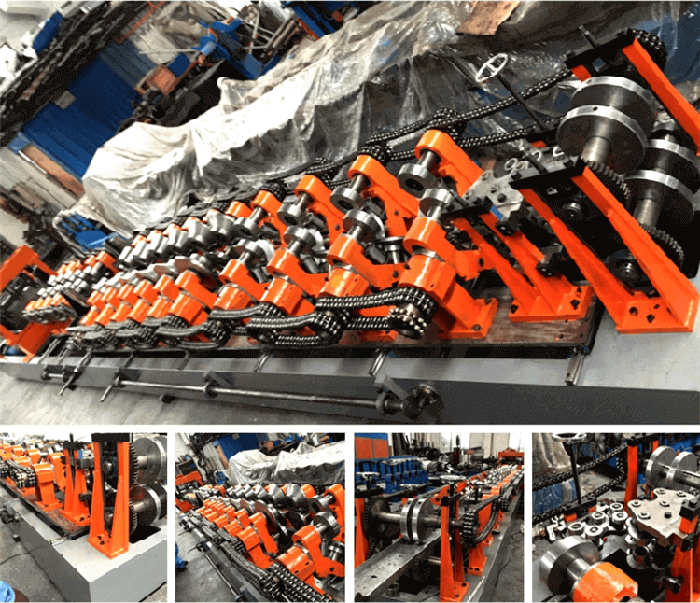

| Forming Steps | 13steps+3steps for reshaping |

| Forming Speed | 15m/min |

| Edge for Z purline | 15-25mm |

| Height of Z Purline | 30-70mm |

| Width of Z Purline | 100mm-300mm |

| Forming Thickness | 1.0-3.0mm |

| Tolerance for cutting | ±2.0mm |

| Tolerance for Forming | ±2.0mm |

| Straightness | 2mm/m |

| Material for All Roller | Gcr15 steel with heat treatment |

| Material of principal axis | High grade 45# forged steel |

| Sprocket wheel | 45# steel high-frequencies quench |

| Cut-off system | Hydraulic cutting device |

| Material for Blade | Cr12 mold steel with quenched treatment 60-62°C |

| Material for frame of machine | Fine welded structural steel; |

| Material for producing theZ Purline | GI Steel with Min.420 Mpa ( JIS G 3302 SGC440OR EN 10346 S350GD ) |

| Painted Color | Red or Customization |

Main Accessories:

| (1) Main Purlin Forming Machine; |

| (2) 5 Tons Manual Uncoiler ; |

| (3) Automatic Guide Device; |

| (4) Hydraulic Motor System; |

| (5)PLC Computer Controlling System With Touch Screen ; |

| (6) Automatic Adjustable Hole Distance Device; |

| (7) Hydraulic Pre-punching Holes Device; |

| (8) Hydraulic Pre-cutting Device |

| (9) Reshaping Device; |

| (10) Rib Rollers; |

| (11) Run Out Table(10 pcs); |

| (12) Tools; |

| (13) Operation Manual,drawing for changing parts |

| (14) Free supply 10pcs bearing, 1.5m chain, 10pcs chain connection pins; |

| (15) Operation Manual. |

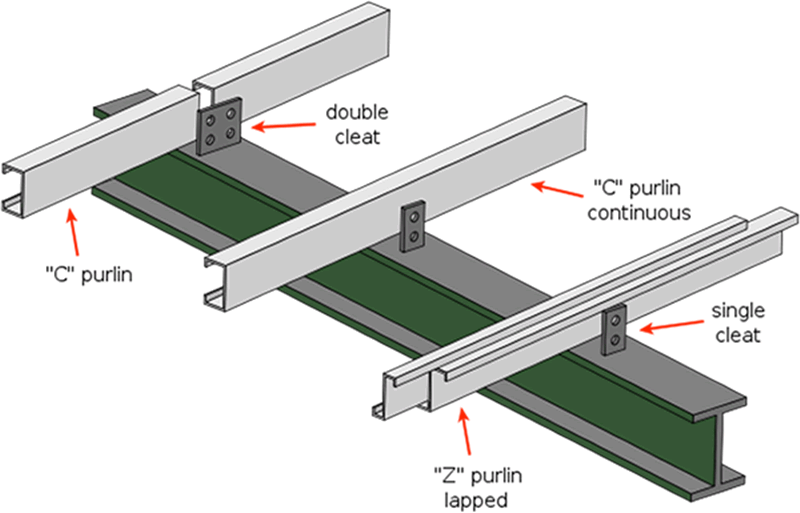

Here is the Z purline using manual in working status.

- Metal wire equipment

- Stud & Track Machine

- C & Z Purline Machine

- Shutter Door Machine

- Window frame machine

- Door Frame Machine

- House Frame Machine

- Container House Machine

- Struct Channel Machine

- Ceiling Panel Machine

- Villa Frame Machine

- High speed rolling machine

- Furring Hat Machine

- Cable Tray Machine

- Embossing machine

- Metal roof sheet machine

- Steel floor deck machine

- Decoiler

- Sliting and Cut to length line